United States

Production and Processing

“Scientists investigate that which already is; Engineers create that which has never been.''

- Albert Einstein

Processing comprises of all the strategies you have available at your disposal to urge the action of the process while production is the act of manufacturing or creating something.

This field requires people with the ability to complete production of goods in the most efficient and cost effective ways possible. It includes a range of activities including the design and planning activities, utilization of resources, cost control procedures etc.

So, here are the top career & courses we’ve handpicked for the one who is eager to get new skills regarding Production and Processing but confused about where to begin from. Let's get right into it.

Career Scope in Production and Processing

With a degree in production and process engineering you can earn jobs in automobile industries, producing industries, IT companies, construction industries, and many other alternatives from government and private departments with renounced titles a number of them as mentioned:

Job Titles:

• Engineering Plant Production Manager

• Industrial Production Managers

Courses in Production and Processing

1. Production Engineering

Production Engineering is the backbone of every industry. It is a specialised field of Mechanical Engineering. This field deals with the complete process of manufacturing & technology hands in hands with management science to provide customers with high- quality materials.

Skills:

- Design efficient production process

- Problem- solving skills related to the production

- Constructively utilize technical knowledge to maximize productivity and profit

- Ensures effective and feasible production cost to the organization

2. Industrial and Production Engineering

The objective of this course is to enable engineers to boost efficiency and effectiveness of the production sector. This includes the curriculum of basic mechanical engineering subjects.

This course aims to make under-graduates compatible with the fast and vast emerging needs of the industry. The most leading manufacturing companies look for engineers who specialize in Industrial Production to reduce cost, increase efficiency and make their products marketable in the competitive era.

Skills:

- Strong communication skills

- Ability to adapt in numerous situations

- Curious to learn and problem-solving ability

- Team player

3. Industrial & Systems Engineering

Industrial and systems engineering utilized in the improvement of advanced engineering systems to boost the efficiency of the processes and therefore the quality of the products. These engineers create use of technologies, materials and resources to ensure the production processes reach their targeted goals. The firms use engineers’ technical skills to understand the vast structural works and to apply business and team management knowledge to increase productivity.

Skills:

- Good math & science skills

- Excellent communication/salesmanship

- Creative drawback resolution

- Strong time management and team management skills

4. Manufacturing Engineering

This focuses on the research, analysis and development of manufacturing systems, processes, machines and instruments – driving forward changes within the lives of people and societies, furthermore as national and international economies. It will provide you with a detailed understanding of each level of the manufacturing process, combining skills in mathematics, arithmetic and business to develop innovative ways for designing & planning systems and processes and the way to keep pace with this ever-changing industry.

Skills:

- CAD (Computer-aided design) software knowledge

- Analytical skills

- Commercial awareness and business skills

- A practical and logistical approach to solving problems

5. Engineering Management

Engineering management is a broad career field that brings along the technological problem-solving ability of engineering and the organizational, administrative, and planning abilities of management to oversee the operational performance of complex engineering driven enterprises. A Master of Engineering Management (MEM) professional seeks a graduate degree as a qualifying certification for a career in engineering management.

Skills:

- Good judgment skills

- Mechanical aptitude and problem- resolution skills

- Solid academic background

- A strong desire for potency, planning and profit of the organization

FREE COURSES

The below courses provide a good overview on the study area

- Fundamentals of Manufacturing Processes on edX.org

- Digital Technologies and the Future of Manufacturing Specialization on Coursera

- CAD and Digital Manufacturing Specialization on Coursera

An introduction is provided in the below video

Frequently Asked Questions

Let’s take a look at some commonly asked questions by students.

Production engineering is a backbone of every industry. It is a specialisation of mechanical engineering branch. This field deals with the complete process of manufacturing and technology and at the same time, also caters to management science to provide customers with the high-quality materials.

One must have a knack to develop and design efficient production process and problem solving skills related to a particular area of production. Furthermore, one must possess the skill to constructively utilize technical knowledge in order to maximize productivity and profit. Furthermore, one should even keep in mind to ensure effective and feasible production cost to the organization.

Process engineering comprises the development of all the strategies one has available to urge action of process. It mostly deals with improving quality control of the produced material, costs and other techniques for maximizing the fruitful manufacture and distribution of goods.

The top 5 career courses in the given field include production engineering, industrial and production engineering, industrial and systems engineering, manufacturing engineering and engineering management.

Strong communication skills and capability to adapt in case any new situation occurs and tackling it efficiently are two skills one must possess apart from good technical skills. Being a team player is also very important as most of the work is supposed to be done in a team. Furthermore, curiosity to learn and advanced problem solving quality makes you even better-suited for the given career field.

This course enables engineers to boost efficiency and effectiveness of this industry. This course totally complements the emerging needs of the industry. Most of the leading manufacturing companies look out for engineers who specialise in industrial production so as to reduce cost, increase efficiency and make products marketable in the increasingly competitive era.

Manufacturing engineering focuses upon research, analysis and development of manufacturing systems, processes, machines and instruments and driving the changes within the lives of people and society. It combines skills in mathematics, arithmetic and business to develop innovative ways for designing and planning systems and processes. It even demands an engineer to be skilled in CAD, analytics, commercial awareness and a logistical approach to solve problems.

Engineering management can be considered as a broad career field that brings along the technological problem-solving ability of engineering and the organizational, administrative, and planning abilities of management in order to oversee the operational performance of complex engineering driven enterprises. A Master of Engineering management professional seeks a graduate degree as a qualifying certification for a career in engineering management.

With a degree in production and process engineering one can earn jobs in automobile industries, producing industries, IT companies, construction industries and many other alternatives from government and private departments with renounced titles. You can explore more about this career on –

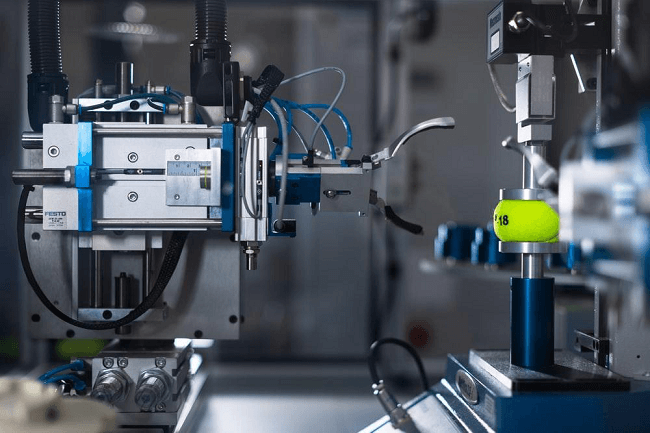

Automation has had a very great influence since its advent on production and process engineering. This includes inclusion of robots to load and unload machines, moving material from one place to another or turn stations for the next operation. By automating a production facility, a shop can increase production, reduce cycle times and become more competitive in the marketplace as well.